Products & Services

What We Offer

At SeaQuest, we are committed to optimal delivery and implementation of production optimization processes in a safe, reliable and timely manner, thereby adding value to our clients and sustaining our competitive edge.

Safety is not just a policy; it’s our philosophy

Safety is often at a critical point in any environment where hydrocarbons are present. Our operational capabilities helps plant operators complete HSSE critical tasks during startup operations, maintenance-related shutdowns and also for installation and commissioning operations

Our Services

First Oil Advisory Services

At SeaQuest, we have a dedicated team of professionals committed to unlocking the potential of new oilfields through expert guidance and innovative solutions – Empowering you with comprehensive first-oil advisory and management services.

Our team of experienced professionals will guide you through:

- Drilling

- Well Completion

- Well Clean-up

- Facility Commissioning and start-up

The project’s delivery section covers our First Oil delivery track record.

Electrical and Instrumentation Services

SeaQuest offers comprehensive E&I services which include the design, installation, Maintenance, and enhancement of intricate systems. Our dedicated professionals prioritize productivity and work safety.

Benefits from our experienced team include:

- Control valve installation and maintenance

- DCS, PLC, SCADA, and Emergency shutdown system installation and maintenance

- Routine and emergency maintenance for E&I equipment

- Troubleshooting, repair, preventive and corrective maintenance, modification, design, installation, and commissioning of E&I equipment

- Preparation of E&I engineering deliverables, including specifications, instrument datasheets, and logic diagrams

- Fire & Gas Detectors & Alarm Device installation and maintenance

- Input provision and review of engineering drawings (E&I drawings)

SeaQuest optimizes operations and prioritizes safety for efficient system functionality.

Production Optimization Services

- Well clean-up/stimulation Services

SeaQuest provides well clean-up packages designed to optimize your oil well performance. Our specialty well stimulation chemicals – Microemulsion Chemical Technology (emulsion breaker) can tremendously increase the production (& productivity index) from your producing wells which are suffering from near wellbore impairment, by enhancing fluid flow to the near well bore region. We have a complete set of pre-production and production equipment with seasoned technical professionals that operate to guarantee seamless delivery.

In comparison with traditional upstream installations, this approach eliminates separate flowlines, separators, heaters treaters, intermediate storage tanks, gas flares, compressors, complicated pumping facilities, etc. Multiphase pumps need neither space-intensive separation devices at the wellhead nor separate pumps, compressors, or pipelines to transport gas and fluid to the central collection areas.

Our MPP is a volumetric pump, with a high gas volume fraction (GVF)

Well Testing | MER | Extended Well Testing

SeaQuest utilizes cutting-edge technology to deliver well-test services. Our team consists of well-qualified and experienced personnel who are equipped to handle your specific needs. We employ standard equipment, adhere to the best industry programs, and implement rigorous quality assurance, quality control (QA/QC), and health, safety, and environment (HSE) practices.

Our services cover the entire spectrum of well testing, from exploration and appraisal to production. By ensuring the collection of reliable data, we provide valuable insights that contribute to the optimization of your assets. SeaQuest is dedicated to delivering exceptional results and supporting the success of your operations.

SeaQuest OFC is a subsidiary of SeaQuest EPS dedicated to providing solutions in Flow Assurance and Optimization services including fluid management operations to international oil companies (IOCs) operating in the Nigerian oil industry as well as National oil companies (NOCs).

Our commitment to partnering with leading global technology companies and employing industry specialists and professionals has ultimately given us an edge and reputation in the oil field chemical space. With excellent service delivery deeply rooted in the very core of our entire business offerings, we are vested in improved technology and service development.

Our Services

- Production and specialty chemicals.

- Drilling, completions, and specialty chemicals

- Chemical and oil additives.

- Industrial and commodity chemicals

- Technical service support to clients

- Field management and surveys

- Produced water treatment

- Laboratory Services

- Technical/commercial recommendation

- Consultancy

Key Account Management

- Dedicated account management.

- Product development in conjunction with technical partners.

- Workshops, training, and seminars for client staff.

- Production Chemicals

We provide oilfield production chemicals that help our client optimize flow while ensuring a reduction in environmental impact. We provide technical chemical management programs for operators by performing auditory services to optimize the required product range and appropriate application of products.

RANGE OF CHEMICAL PRODUCT

- De-oilers

- Tailor-made demulsifier

- Asphaltene inhibitors

- Asphaltene dissolvers

- Paraffin inhibitors

- Paraffin dissolvers

- Wax inhibitors

- Pourpoint depressants

- Corrosion inhibitor

- Wastewater treatment chemicals

- Tank cleaning chemicals

- Scale Inhibitors

- Scale dissolvers

- Salt dispersant

- Oxygen and H2S Scavengers

- Defoamers

- Foamers and foamsticks for gas well deliquification.

- Drilling and completion chemicals

- Sub-sea fluids

- Stimulation chemicals

- Pipeline & process chemicals

- Water solutions

- Utility chemicals

- Laboratory Cabin

Our onsite two-tier laboratory is equipped with state-of-the-art testing equipment to accurately handle crude oil quality and flow assurance monitoring operations. We employ international standard operating procedures for crude oil quality testing and production optimization processes

TECHNICAL SPECIFICATION

- Standard 15x8ft units are CSC plated and PU insulated.

- Load tested and supplied with fully certified lifting gear A60 fire rated.

- Equipped with a fire extinguisher.

- Equipped with an eye wash station.

- Fitted with ventilation and fume extractors.

- Equipped with 1.5hp air conditioning.

- Quick connections for mains power and remote alarms.

- 240v power 13amp and 15amps outlets.

- Two (2) Teflon wash sinks.

- Plumbing system with ½’’discharge line and 3/8’’ supply line.

- Fitted with Epoxy tabletop workbenches.

- Fitted with x3 wall cabinets.

- Fitted with x4 standing cabinets

- Equipped with 3 sitting stools.

- Early Production Facility (EPF)

Our EPF is designed with some flexibility, to enable asset owners to achieve positive cash flow ahead of the permanent surface production facility, while maintaining all internationally accepted standards, to bring maximum benefits to our clients. It is built to handle oil and gas while providing opportunities for production data acquisition and chemical treatment of the produced fluids.

With our qualified personnel, we provide EPF operate-and-maintain (O&M) services

- Multi Phase pumping

Our multiphase pumping technology has the unique ability to boost/transport unprocessed hydrocarbon (gas and liquids) via dedicated trunk lines, over long distances without phase separation (single phase) to a central processing facility (e.g., flow station or gathering station).

In comparison with traditional upstream installations, this approach eliminates separate flowlines, separators, heaters treaters, intermediate storage tanks, gas flares, compressors, complicated pumping facilities, etc. Multiphase pumps need neither space-intensive separation devices at the wellhead nor separate pumps, compressors, or pipelines to transport gas and fluid to the central collection areas.

Our MPP is a volumetric pump, with a high gas volume fraction (GVF)

- METERING

SeaQuest offers a wide range of metering solutions which includes;

- The PPM Analyzers: Highly sensitive real-time instruments developed specifically for use to measure parts per million moisture levels in a hydrocarbon liquid.

- Water-cut Analyzer: Real-time water measurement device for a crude process utilizing patented Microwave Oscillator Load Pull technology.

- Fiscal Skids: Custom designed for Custody Transfer applications such as pipeline and tanker unloading facilities.

- Pro-cut: For oil payload sampling prior to Tanker Truck unloading of heavy oil. It is effectively a Mid-Range Analyzer modified for Pour-in analysis.

- The Compact Cyclone Multiphase Meters: Real-time measuring systems for oil, gas, and water flowing from production wells. Used both onshore and offshore for fast, accurate, and reliable well testing. Multiphase flow meters are used in place of traditional two-phase and three-phase test separators.

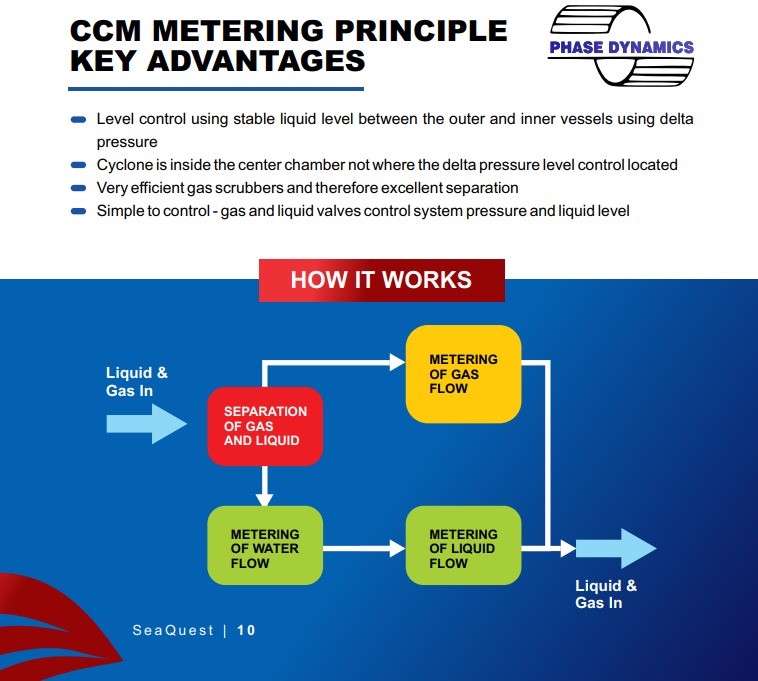

- CUTTING-EDGE MEASUREMENT SOLUTIONS (COMPACT CYCLONE MULTIPHASE METER)

Component

- Control Systems Water Analyzer Separator

- Pneumatic Gas & Liquid Valves

- Coriolis Gas & Liquid Flow Meter

Key Advantages

- Simple and Complete Electronics Without Extra PLC’s

- Easy Maintenance by Local Personnel

- High accuracy – Determined only by Separation Efficiency

- “Off the shelf” Standard Flow & Measurement Meters

- All meters are calibrated at the factory, no need for field calibrations

- Special design cyclone separator is small in size but large in capability of flow ranges

Drilling and Evaluation Services

Rental Services

Project Delivery

Installation of Water Cut Analyzer for water in oil measurement (Water cut meters for internal production measurement)